Product Description:

Condensate Polishing Filter

Condensate Polishing Filter is a highly efficient and reliable product designed for the clarification of condensate in various industries. It is an essential component for maintaining the purity of condensate in power plants, chemical plants, and other industrial facilities.

Design Flow Rate:

The Condensate Polishing Filter has a design flow rate of 3.9m³/h~4.5m³/h, making it suitable for handling large volumes of condensate.

Filter Material:

The filter material used in this product is polypropylene, which is known for its high strength, durability, and chemical resistance. This ensures that the filter can effectively remove impurities from the condensate without getting damaged.

Support Core:

The support core of the Condensate Polishing Filter is made of reinforced polypropylene, providing added strength and stability to the filter. This allows it to withstand high differential pressures and maintain its shape and performance over time.

Filter Area:

The filter area of the Condensate Polishing Filter ranges from 0.4-0.7㎡, providing a large surface area for efficient filtration. This results in a high flow rate and better removal of impurities from the condensate.

Maximum Operating Differential Pressure:

The Condensate Polishing Filter can withstand a maximum operating differential pressure of 2.8bar at a temperature of 65℃. This makes it suitable for use in a variety of industrial settings where high pressure and temperature conditions are present.

Key Features:

- Condensate Clarification: The Condensate Polishing Filter effectively removes impurities from the condensate, ensuring its purity and quality.

- Condensate Polisher: This product acts as a polisher for the condensate, providing a final stage of filtration to remove any remaining impurities.

- Condensate Polisher Filter: The Condensate Polishing Filter is specifically designed to meet the filtration needs of condensate polishing, making it a highly efficient and reliable choice.

- High Efficiency: With its large filter area and high flow rate, the Condensate Polishing Filter can effectively remove impurities and ensure the purity of the condensate.

- Reliable Performance: The use of high-quality materials and reinforced support core ensures that the Condensate Polishing Filter delivers consistent and dependable performance over time.

In conclusion, the Condensate Polishing Filter is an essential product for industries that rely on clean and pure condensate. With its high efficiency, reliable performance, and durable design, it is a cost-effective solution for maintaining the quality of condensate in various industrial processes.

Technical Parameters:

| Product Name |

Condensate Polishing Filter |

| Max. Filter Temperature |

85°C |

| Filter Material |

Polypropylene |

| Filter Area |

0.4-0.7㎡ |

| Filter Certification |

ISO 9001, ISO45001 |

| Maximum Operating Differential Pressure |

2.8bar, 65℃ |

| Filter Rating |

1-10 Micron |

| Filter Size |

70'' |

| Design Flow Rate |

3.9m³/h~4.5m³/h |

| Support Core |

Reinforced Polypropylene |

| Bottom Thread |

M6, M8, M10, 3/8 |

| Key Features |

Condensate Filtration, Condensate Clarification, Condensate Polisher |

Application and Scene:

The Condensate Polishing Filter is widely used in the condensate filtration and purification process in various industries such as power plants, petrochemical plants, and industrial processes. It is an essential component in the water treatment system, ensuring the quality and purity of condensate water for further use.

Imagine a power plant that produces a large amount of steam as a byproduct. In order to reuse the steam, it needs to be condensed back into water. However, during the condensation process, impurities and contaminants can accumulate, affecting the quality and efficiency of the steam. This is where the Condensate Polishing Filter comes into play.

Installed in the condensate water system, the filter effectively removes impurities and contaminants, ensuring the purity and quality of the condensed water. This purified water can then be reused for various purposes, such as boiler feed water, cooling water, or even as process water in industrial processes.

In the petrochemical industry, the Condensate Polishing Filter plays a crucial role in purifying the condensate water produced during the refining process. This ensures the quality of the water used in various operations, preventing potential damage to equipment and ensuring the safety of the final products.

In industrial processes, where water is used for various purposes such as cleaning, cooling, and production, the Condensate Polishing Filter is necessary to maintain the quality and purity of water. It helps to remove impurities and contaminants, preventing potential damage to equipment and ensuring the quality of the final products.

The scene of a Condensate Polishing Filter in action is a power plant, petrochemical plant, or industrial facility, where the filter is installed in the water treatment system. It is a highly efficient and reliable solution for maintaining the purity of condensate water, ensuring smooth operations and preventing potential hazards.

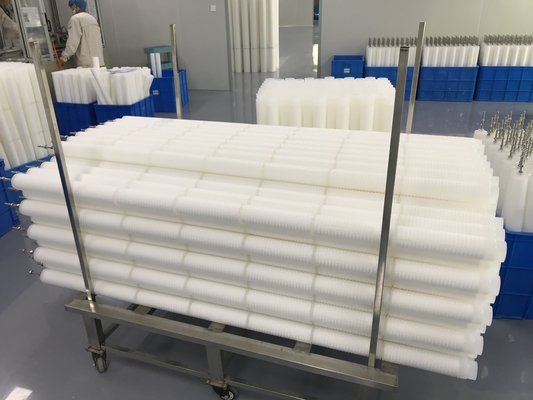

Packing and Shipping:

Packaging and Shipping of Condensate Polishing Filter

The Condensate Polishing Filter is carefully packaged and shipped to ensure its safe delivery and protection during transit.

Packaging

The filter is first wrapped in a layer of protective material to prevent any scratches or damages. It is then placed in a sturdy cardboard box with additional padding for extra protection. The box is sealed securely to prevent any movement during transportation.

For larger orders, the filters are packaged in wooden crates for added protection.

Shipping

The Condensate Polishing Filter is shipped via reputable and reliable courier services to ensure timely and safe delivery.

The shipping method and carrier can be chosen by the customer or recommended by our team based on the destination and urgency of the order.

Once the filter is shipped, the customer will receive a tracking number to monitor the status of their shipment.

For international orders, the necessary customs and export documents will be provided to facilitate the smooth delivery of the product.

We strive to ensure that our packaging and shipping methods meet the highest standards to guarantee the safe arrival of the Condensate Polishing Filter to our customers.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is PULLNER.

- Q: What is the model number of this product?

A: The model number of this product is PHFZ.

- Q: Where is this product manufactured?

A: This product is manufactured in China, ShangHai.

- Q: What certifications does this product have?

A: This product is certified with ISO19001, ISO14001, and ISO45001.

- Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 100.

- Q: Is the price negotiable for this product?

A: Yes, the price for this product can be negotiated.

- Q: How is this product packaged?

A: This product is packaged with a carton box after a poly bag.

- Q: What is the estimated delivery time for this product?

A: The estimated delivery time for this product is 5-8 working days.

- Q: What are the accepted payment terms for this product?

A: The accepted payment terms for this product are L/C, D/A, D/P, T/T, Western Union, and MoneyGram

- Q: What is the supply ability for this product?

A: The supply ability for this product is 100 pieces per day.

Application Field:

1. Food and beverage 2. Sea water desalination 3. Power plant condensation 4. Petrochemical engineering

Pullner Production Process:

Company Profile:

Shanghai Pullner Filtration Technology Co., Ltd. was established in May 2011 with a registered capital of 26 million yuan. It has a 100,000-level purification workshop of 3,000 m² and a local thousand-level purification laboratory. It is a research and development, production and sales of microporous membrane filtration equipment, filtration system in one of the well-known enterprises.

The company's products are mainly used in Microelectronics, Fine chemicals, New energy, Seawater desalination, Biotech, Latoratory and other fields. Covering Liquid crystal panels, Semiconductor chips, High-purity chemicals, Raw materials, Condensate filtration, Reclaimed water reuse more than a dozen industries.

Pullner Laboratory:

Our company has ISO19001, ISO14001, ISO45001 certificates, we are high-tech enterprise with multiple patent certificates. Approval vendor of Saudi Aramco.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews