Condensate Polishing Filter

Ideal solution for industrial steam systems to remove impurities and ensure condensate recycling with high-efficiency filtration performance.

Product Overview

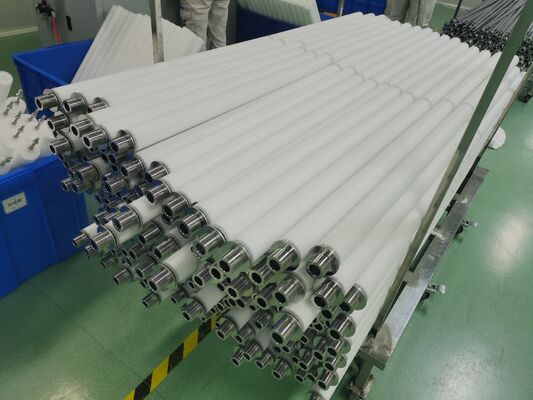

Our Condensate Polisher features a 6.5㎡ filter area, making it one of the most efficient filters available. With filter ratings of 1μm, 4μm, and 10μm, it effectively removes even the smallest impurities from condensate streams, protecting power plants from corrosion and scaling that can lead to costly downtime and repairs.

Constructed from durable Polypropylene material known for excellent chemical resistance, our filters withstand harsh power generation conditions and operate reliably for extended periods. The design flow rate of 3.5m³/h~4.5m³/h makes it suitable for diverse power generation applications.

Beyond high-performance filtration, our Condensate Polisher also functions as a Condensate Strainer, removing both impurities and larger debris to protect downstream equipment. This makes it an essential component for ensuring smooth and efficient plant operation.

Technical Specifications

| Specification |

Details |

| Product Name |

Condensate Polishing Filter |

| Filter Material |

Polypropylene |

| Available Lengths |

70'', 60'' |

| Maximum Filter Temperature |

85°C |

| Filter Rating |

1μm, 4μm, 10μm |

| Inlet Water Quality |

<2000 Ppb |

| Filter Area |

6.5㎡ |

| Design Flow Rate |

3.5m³/h~4.5m³/h |

| Max Operating Differential Pressure |

3.0bar/65℃ |

Key Features

- High-efficiency condensate straining and filtration

- Advanced condensate purification capabilities

- Durable Polypropylene construction for chemical resistance

- Multiple filter ratings for comprehensive impurity removal

- Protection against corrosion and scaling in power systems

- Suitable for high-pressure and high-temperature applications

Industrial Applications

The PULLNER PHFZ Condensate Polishing Filter is ideal for power plants, refineries, chemical plants, and other industrial facilities where condensate quality is critical. It effectively removes impurities including iron oxide, copper oxide, and other contaminants to meet required standards.

Easy to install and maintain, this filter provides a cost-effective solution for condensate clarification, polishing, and filtration applications across various industries.

Customization & Certification

Model PHFZ filters are manufactured in Shanghai, China with comprehensive certifications including ISO19001, ISO14001, ISO45001, and ISO 9001 standards. The filter construction features Polypropylene material with PP cage/core/end cap components.

Minimum order quantity: 100 units. Competitive pricing with flexible payment terms including L/C, D/A, D/P, T/T, Western Union, and MoneyGram. Supply capacity: 100 pieces per day with 5-8 working day delivery.

Packaging & Shipping

Each condensate polishing filter is securely packaged in cardboard boxes with foam padding to prevent transit damage. Packages include installation instructions and necessary hardware.

Free standard shipping within the United States. International shipping costs calculated at checkout. Orders processed and shipped within 1-2 business days with tracking numbers provided via email.

Manufacturing Excellence

State-of-the-art production facilities ensuring quality manufacturing processes and consistent product performance.

Company Profile

Shanghai Pullner Filtration Technology Co., Ltd., established in May 2011 with 26 million yuan registered capital, operates a 3,000 m² 100,000-level purification workshop and local thousand-level purification laboratory. As a renowned enterprise, we specialize in research, development, production, and sales of microporous membrane filtration equipment and systems.

Our products serve multiple industries including Microelectronics, Fine chemicals, New energy, Seawater desalination, Biotech, and Laboratories. Applications span Liquid crystal panels, Semiconductor chips, High-purity chemicals, Raw materials, Condensate filtration, and Reclaimed water reuse across dozens of industries.

Quality Assurance Laboratory

Advanced laboratory facilities ensuring rigorous quality control, product testing, and continuous research and development for filtration technology innovation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews